Home>> Roller Bearing>>Roller Bearing >> Cylindrical Roller Bearings1

Cylindrical Roller Bearings1

Cylindrical Roller Bearingscan accommodate radial loads and operate at high speeds. Applications of cylindrical roller bearings are mostly found in middle-sized and large-sized motors, electricity generators internal combustion engines, gas turbines, machine tool spindles, deceleration devices, unloading and lifting machines and other industrial machines.

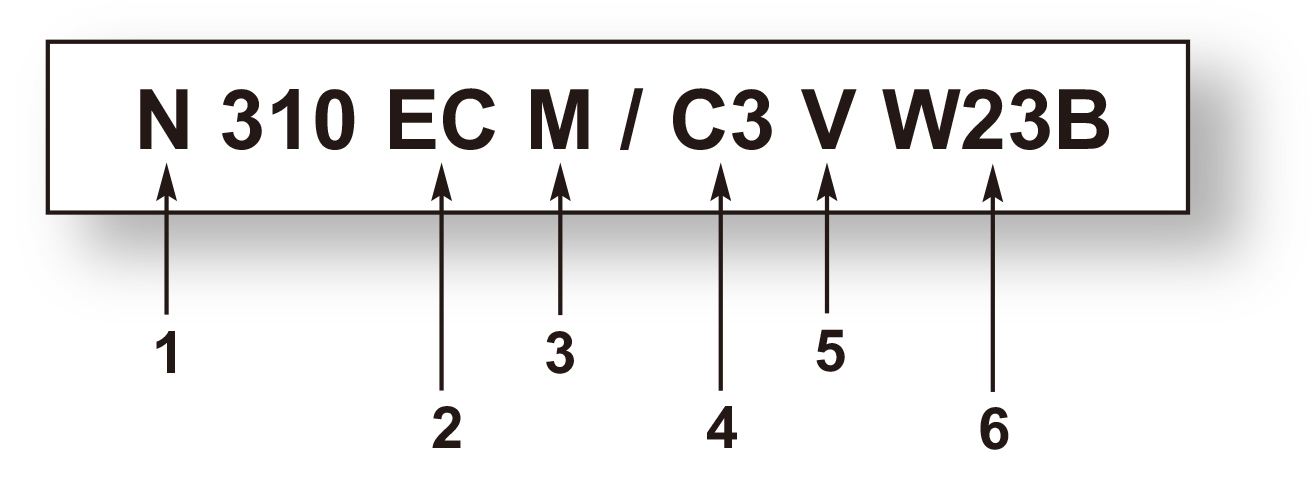

The Meaning of Suffix

1. Basic Design | 2. Internal Design | 5. Variations | ||||

N | Two integral flanges on inner | EC | Increased capacity plus | BV | V + surface treated rollers | |

ring, flangeless outer ring | improved roller end to flange | 2LS | Two land riding contact seals | |||

NCF | Full complement, two flanges | contact | V | Full complement bearing | ||

on inner ring, one flange on | 3. Cage Designations | without cage | ||||

outer ring, with snap ring | J | Pressed steel cage, rolling | 6. Special Features | |||

NJ | One integral flange on inner | element centred | VA 301 | Special bearing specifications | ||

ring,two flanges on outer ring | M | Machined brass cage, rolling | for traction motors | |||

NJG | Full complement with one | element centred | VA 3091 | VA 301 + VL 0241 | ||

flange on inner ring and two | MA | Machined brass cage, flange | VL 0241 | Aluminum oxide coating on | ||

flanges on outer | outer ring centred | inner ring for electrical | ||||

NNC | Double row CRB with one | ML | One piece form turned, window | insulation | ||

outer ring integral flange | type brass cage, ring centred | VQ 015 | Inner ring with crowned | |||

and one flange ring | M2 | Solid brass drilled cage, roller | raceway for increased | |||

NNCF | Two-row, full complement, three | guided | permissible misalignment | |||

flanges on inner ring, one flange | P | Injection moulded cage of | W23B | Special features for traction | ||

on outer ring with snap ring | fiberglass reinforced | motor bearings | ||||

NNCL | Double row CRB with no outer | polyamide. | ||||

ring integral flanges, one | PH | PEEK, hi-temp polyether ether | ||||

centrally located snap ring | keytone cage | |||||

NNF | Two-row, full complement | 4. Radial Internal Clearance | ||||

NU | Two integral flanges on outer | C1 | Clearance < C2 | |||

ring, flangeless inner ring | C2 | Clearance < Normal | ||||

NUP | Two integral flanges on outer | C0,CN | Normal clearance (no symbol | |||

ring, one integral flange on inner | shown) | |||||

ring and one loose flange on | C3 | Clearance >Normal | ||||

inner ring | C4 | Clearance >C3 | ||||

RN | N type without outer ring | |||||

RNU | NU type without inner ring | |||||